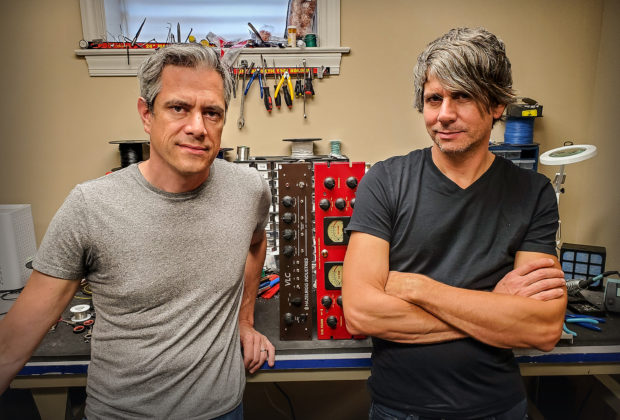

It’s the story that has been told by innovators, perhaps since the dawn of history: they started their business when they saw that they needed something that no one else offered. It’s in large part the story told by Philadelphia brothers Geoff (pronounced “Joff”) and George Hazelrigg when they set out to fabricate handmade audio components. The two men connected with engineering and industry gear veteran Doug Fearn and struck an agreement in 2015 to make his pieces. Indeed, he still designs all of the circuits. Since they began, their driving vision has been to offer the best audio equipment available. Among their Solution Series are the VT-1 and VT-2 mic preamps, the VT-4 and VT-5 tube equalizers and the VT-7 compressor. In addition to being gear aficionados, they also form two-thirds of the Hazelrigg Brothers acoustic jazz trio.

“We got into gear because we’d produced records for a variety of people,” George says of their expansion into assembling preamps and the like, “and we wanted to make them sound better. We always took some of the money we’d made producing and put it into gear. Soon we saw that we were making commercial stuff. We’d had a lot of vintage pieces but, of course, they break. Not because they’re not built well, but because they’ve been used. Those are hard to get serviced. One day Geoff said he was going to fix one of our pieces. I asked if he knew how to do that and he said, ‘Well, electronic repair guys do it. How hard can it be?’ He came back and said, ‘You know, we can build some of this stuff.’ The things he made were better than what we’d buy from a manufacturer and at a third the cost. But it was never our goal to become manufacturers.”

It wasn’t long until a friend suggested that they reach out to Doug Fearn. George took that advice and they soon joined forces. “I looked up the company and found that they were about an hour from my house,” George recalls. “I emailed Doug, we got together and starting doing assembly for him. But there was never any intention of having a business of it. It was something I enjoyed and it gave us access to the best gear we could get our hands on. It was like the ultimate sound came to us. Somewhere along the line, we had a discussion about building equipment that would be accessible to more people. That’s how we came out with the VLC. We had a good year doing that and then Doug asked us if we wanted to manufacture all of his products.”

There aren’t many electronic offerings that are made by hand these days. George and Geoff see value––both tangible and intangible––in building their gear manually. “Having your eyes and hands on every component gives you a better product,” George asserts. “Even the smallest piece is of the highest quality,” Geoff adds. “Most products are run off of an assembly line by a machine that welds a cheaper version of a component that’s a third the size to a PC board. When that board craps out, which it will, you throw it away. The [individual] pieces are all service-mounted and are too tight to get in and repair. Our products are built for a 50-year life span.”

One of the biggest challenges the brothers encountered over the past six years with their products was getting the paint correct and, moreover, finding a qualified vendor to complete the work. It may sound like a simple undertaking, but anyone who underestimates the difficulties of such a choice does so at his or her peril. “The paint that we use is [made by] Imron,” George explains. “It’s single-stage polyurethane marine paint that costs eight hundred dollars a gallon. They use it to paint airplanes. It has to be mixed with the correct catalyst, the temperature has to be right and you can’t have dust floating around. We had a lot of trouble initially getting it done by a vendor. The first one was a nightmare. They messed it up––it looked like a scene from Carrie––and wanted to charge us seven hundred dollars. They told us, ‘You should have known that we weren’t capable of doing this.’ I told them ‘I’d love you to say that to a judge.’”

There was also a time when they were courted by a fabricator in China. When both their first and second shipments had glaring faults, they decided that it was better to have their pieces made locally. “There were a lot of fine points that we had to shore up in our vendor chain when we took over,” George recollects. “We’ve also learned that it’s better to have personal relationships with the people who you’re manufacturing with, because they’re partners.”

The Hazelrigg Brothers’ last record, Songs We Like, included covers by a range of artists, such as Men at Work (they’re big fans of the band and are on friendly terms with Colin Hay, who’s also a client), Jimi Hendrix and Led Zeppelin. Indeed, there was a piece of gear that they stopped making that Hay liked and they brought it back at his request. New components are also on their horizon.

Contact dwfearn.com, hazelriggbrothers.com